-

Is Your Engine Breathing Properly? Everything You Need to Know About Choosing the Right Air Filter

2026-01-06

When it comes to vehicle maintenance, many drivers focus heavily on oil changes and tire rotations while overlooking one of the most critical components for engine health: the Air Filter. Recently, automotive experts and enthusiasts have been discussing how hi...rede more -

How to choose the right materials for Filter Elements?

2025-12-26

Materials are the "soul" of filter elements, directly determining their filtration performance, durability, and safety. As a professional OEM/ODM supplier, Ningbo Heyuan Auto Parts Co., Ltd. has accumulated profound experience in materials science and provides...rede more -

What are the key design points of Filter Elements?

2025-12-19

As a leading enterprise in the filter manufacturing field, Ningbo Heyuan Auto Parts Co., Ltd. deeply understands the core points of filter design with thirty years of professional experience. Excellent design is not only about filtration efficiency but also di...rede more

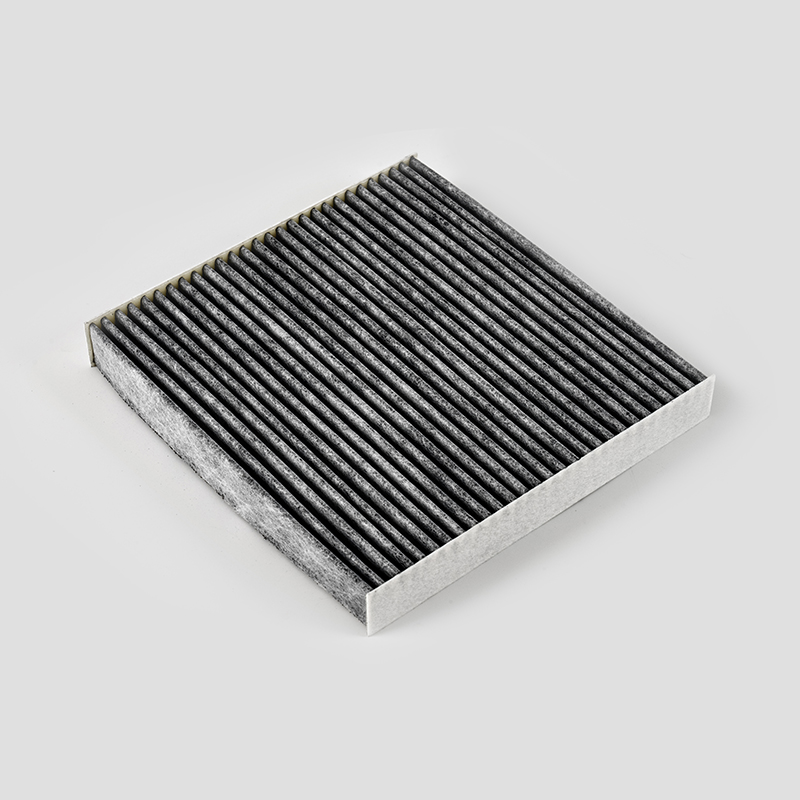

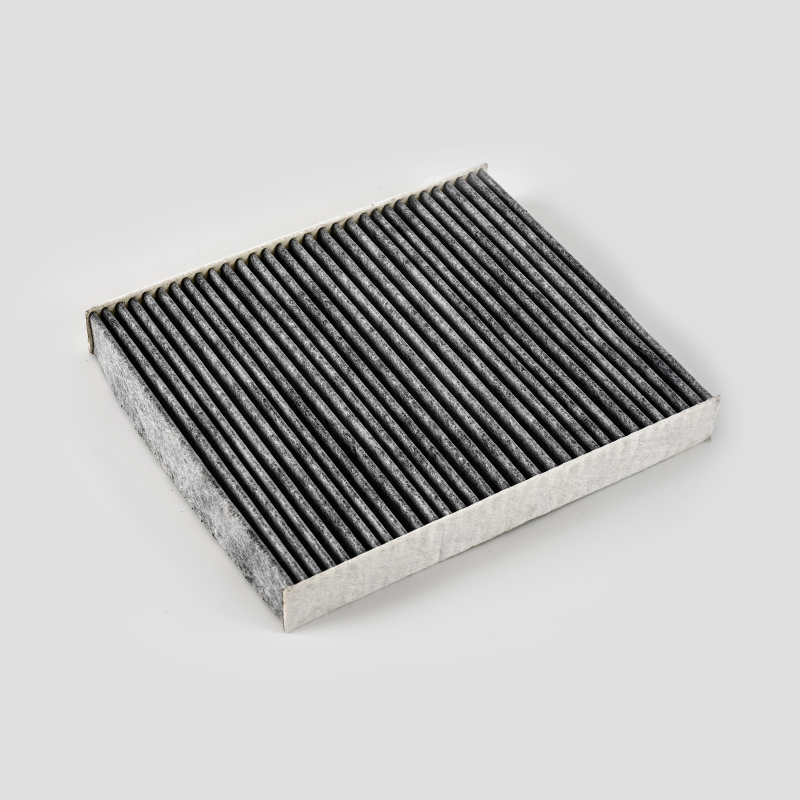

Automotive Carbin Filter Manufacturer

The filter element adopts active carbon plus fiberglass composite, advanced lamination process to ensure ventilation. The activated carbon is made of bamboo carbon, which effectively removes soot, ozone, odor, carbon oxides, pollen, SO2, CO1 and so on. At the same time it has the function of sterilization and deodorization, which can ensure fresh air in the driving room without breeding bacteria, creating a good safe and healthy environment.

WHO ARE WE?

Ningbo Heyuan Auto Parts Co., Ltd. is an integrated trade and manufacturing enterprise specializing in the production of various filters, including air filters, cabin filters, oil filters, diesel filters, gasoline filters, hydraulic filters, and special filters. NBHY produces over 50 million vehicle filtration systems and various filter elements annually, utilizing advanced plastic blow molding, rubber processing, and welding technologies, making it a diversified large-scale manufacturing base in China.

As a professional OEM Automotive Carbin Filter Manufacturer and ODM Automotive Carbin Filter Company, With 30 years of professional design and production experience, NBHY is equipped with modern large-scale production workshops, R&D, business, and office centers, we have strict production, testing equipment and assembly lines. All product development is carried out using computer-aided design, while production strictly adheres to the ISO/TS16949:2009 and ISO9001:2000 quality management systems. Our product quality is highly praised by customers domestically and internationally, with products exported to over a dozen countries and regions, including Europe, the Middle East, and Japan.

Currently, the company mainly provides processing and production services for domestic OEMs and well-known international brands, including over a dozen Fortune 500 companies, and has become an important supplier of filtration systems in China.

-

Industry Experience

0+ -

Modern Intelligent Factory

0+ -

Cooperating Automobile Enterprises

0+ -

Technical Engineers

0+

/ KEEP IN TOUCH

Feel free to ask for any info on NBHY.We are committed to understanding your needs and providing you with the right solution. Our experts will respond to all inquiries within 12 hours.

News

Cabin Filter's performance in filtering odors and harmful gases

1. Activated carbon filtration technology

Ningbo Heyuan Auto Parts Co., Ltd.'s Cabin Filter usually uses activated carbon as one of the core filter materials. Activated carbon has a high specific surface area and adsorption capacity, which can effectively capture and remove odors (such as smoke, food, etc.) and volatile organic compounds (VOCs) such as benzene, formaldehyde and alcohols in the air in the car. Activated carbon effectively neutralizes and eliminates these harmful gases through a combination of physical adsorption and chemical reaction.

2. Multi-layer composite structure

Ningbo Heyuan Auto Parts Co., Ltd.'s Cabin Filter adopts a multi-layer composite structure design, which not only enhances the filtration efficiency but also optimizes air flow. Usually, this structure includes:

Front layer filter material: used to capture large particles such as dust, pollen and hair.

Middle layer activated carbon layer: specially used to adsorb odors and harmful gases.

Back layer high-efficiency filter material: used to further filter small particles to ensure the freshness and safety of the air in the car.

3. High filtration efficiency

Ningbo Heyuan Auto Parts Co., Ltd.'s Cabin Filter undergoes rigorous performance testing to ensure its high filtration capacity under different working conditions. The design of the filter enables it to achieve a filtration efficiency of more than 95% without increasing airflow resistance, effectively blocking tiny particles and harmful gases.

4. Durability and long-term effect

Ningbo Heyuan Auto Parts Co., Ltd. focuses on durability in material selection and manufacturing processes to ensure that the filter can maintain good filtration performance after long-term use. The adsorption capacity of activated carbon is long-lasting. The filter can effectively filter for several months under normal use. Users can replace it regularly to maintain a good effect according to the use environment and the air quality in the car.

5. Performance testing

The company performs performance tests on each batch of cabin air filters during the production process, including filtration efficiency, airflow resistance, etc., to ensure that it meets industry standards and customer needs. The test usually includes the following aspects:

Filtration efficiency test: evaluates the filter's ability to capture particles of different particle sizes.

Airflow resistance test: ensures that the filter does not significantly affect air circulation during use.

6. User experience

Ningbo Heyuan Auto Parts Co., Ltd. fully considered the user experience when designing the Cabin Filter. The low airflow resistance design of the filter allows smooth air circulation in the car, avoiding odor retention caused by excessive filter resistance. At the same time, Heyuan pays attention to customer feedback and continuously optimizes products based on actual usage to ensure that the air quality needs of different users are met.

7. Environmental protection and safety

Ningbo Heyuan Auto Parts Co., Ltd.'s Cabin Filter also pays attention to environmental protection in material selection, ensuring that the materials used are non-toxic, harmless, friendly to the human body and the environment, and provide consumers with a safe and healthy in-car environment.

English

English Español

Español عربى

عربى